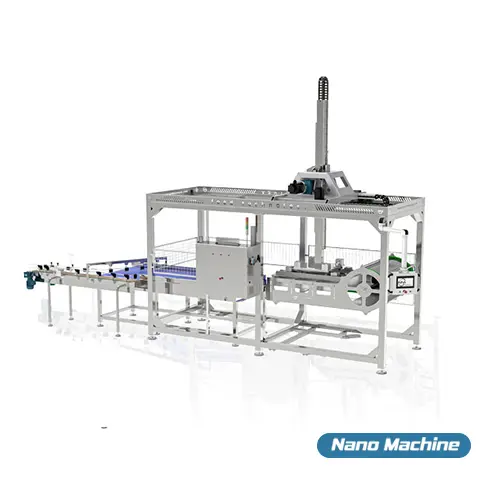

In the canned food, beverage, and packaging industries, the process of feeding and collecting products from production lines or pallets is a crucial and sensitive stage that directly impacts production quality and efficiency. NANO MACHINER has made significant progress in improving this process by introducing the advanced product known as the Magnetic Loader and Unloader for Glasses. This device operates fully automatically and uses a magnetic system to collect products, including cans and glasses of various sizes, from the production line or pallets and transfer them to another production line or pallet. The design of this device not only enhances the speed and accuracy of the process but also prevents damage to the products.

The Magnetic Loader and Unloader for Glass by Nano Machin is engineered with advanced technology, ensuring precise and controlled feeding and collecting of products. This device utilizes a magnetic system that intelligently and accurately collects products from production lines or pallets.

One of the standout features of this device is its vertical and horizontal movement, controlled by a servo motor and smart automation system. This design allows the device to handle products with high speed and exceptional precision, transferring them without impact or damage.

Another key feature is the precise and organized arrangement of products, which ensures optimal use of the autoclave’s capacity. This design not only increases production efficiency but also prevents product damage during handling.

Additionally, the automatic peeling system efficiently removes layers from cans, facilitating the unloading process. This design speeds up the process while also preventing any damage to the cans.

The Magnetic Loader and Unloader for Glass offers several significant advantages for industries:

Fully Automatic Feeding and Collection: The use of a magnetic system and smart automation ensures the process is entirely automatic.

Compatibility with Various Sizes: The device can handle cans and glass containers of different sizes with ease.

Prevention of Product Damage: The precise design and magnetic system prevent impacts and damage to products during handling.

Vertical and Horizontal Movement: Movement is controlled with precision through a servo motor and smart automation system.

Increased Speed and Precision: High-speed and accurate operation reduce production time, enhancing efficiency.

Reduced Human Labor: The automated operation minimizes the need for human intervention, improving workplace safety and reducing labor costs.

Increased Productivity: Reducing time and improving accuracy directly boosts the overall production efficiency.

مشخصات فنی واحد / Unit Technical characteristics

ظرفیت تولید 300 cans/min Production capacity

توان مصرفی 9 kw Motor power

طول 720 cm Length

عرض 210 cm width

ارتفاع 550 cm height

وزن دستگاه 2400 kg weight

The process of this device works as follows:

Product Collection: The device automatically collects products from the production line or pallets.

Product Transfer: The products are transferred to other pallets or production lines accurately and without impact.

Vertical and Horizontal Movement: The servo motor and smart automation system precisely control the device’s movement.

Feeding the Production Line: Products are fed to the production line in an orderly and accurate manner.

If you need advice, our experts will contact you as soon as possible.

This device has applications in various industries, including:

Canned Food Industry: For collecting and feeding canned products.

Beverage Industry: For collecting and feeding beverage bottles.

Food Industry: For packaging food products in cans and jars.

Chemical Industry: For packaging chemical products in resistant containers.

The use of the Magnetic Loader and Unloader for Glass by Nano Machine has numerous positive effects on the quality and efficiency of the production process:

Reduced Process Time: The fast and automatic operation reduces the time needed for collecting and feeding products.

Prevention of Product Damage: The precise design and use of the magnetic system prevent product impact and damage.

Increased Production Efficiency: Reduced time and increased accuracy boost the production line’s efficiency.

Lower Production Costs: The reduction in labor requirements and increased speed leads to a decrease in production costs.

Improved Safety and Hygiene: The absence of manual handling enhances workplace hygiene and safety.

The Magnetic Loader and Unloader for Glass by Nano Machine, with its advanced technology and user-friendly design, has become one of the best options for industries such as canning, beverage production, and packaging. This device not only increases the accuracy and speed of the product collection and feeding process but also reduces costs and enhances productivity, bringing profitability to manufacturers. If you’re looking for a comprehensive solution to improve the product collection and feeding process, the Nano Machine Magnetic Loader and Unloader for Glass is the ideal choice.

With its advanced design, precise performance, and full automation capabilities, the Magnetic Loader and Unloader for Glass by Nano Machine has revolutionized the product collection and feeding industry. This device not only enhances the quality and precision of the production process but also ensures profitability for manufacturers by reducing costs and increasing productivity. If you’re seeking a comprehensive solution to improve the product collection and feeding process, the Nano Machine Magnetic Loader and Unloader for Glass is the best choice.

The Can Loader in Autoclave Basket by Nano Machine, with its advanced design, precise operation, and full automation capabilities, has revolutionized the product collection and arrangement industry. This device not only increases the quality and accuracy of the production process but also ensures profitability for manufacturers by reducing costs and enhancing productivity. If you’re looking for a comprehensive solution to improve the product collection and arrangement process, the Can Loader in Autoclave Basket by Nano Machine is the ideal choice.

Nanos Machine Kian Rastan Company, with 35 years of experience and technical expertise in the design and manufacturing of food industry machinery, is a member of the official Food Machinery Manufacturers Association of Iran. This company is now recognized as a leading reference in the production of mushroom processing machinery, production lines for various canned products, and packaging of cans and bottles in Iran and neighboring countries. We help food producers to create higher-quality and more mechanized products, while increasing the efficiency of their production lines.